Article by Chris Kinsfather | Mar 20, 2017 | AC Drives |

The motor control world can be confusing for sure. With the interchangeability of words, the true meaning of a VFD (Variable Frequency Drive) can sometimes be confused with the term INVERTER. In order to better understand why purchasing a VFD may or may not be the best solution for you we want to start off with a brief and easy to understand definition of what a VFD really is.

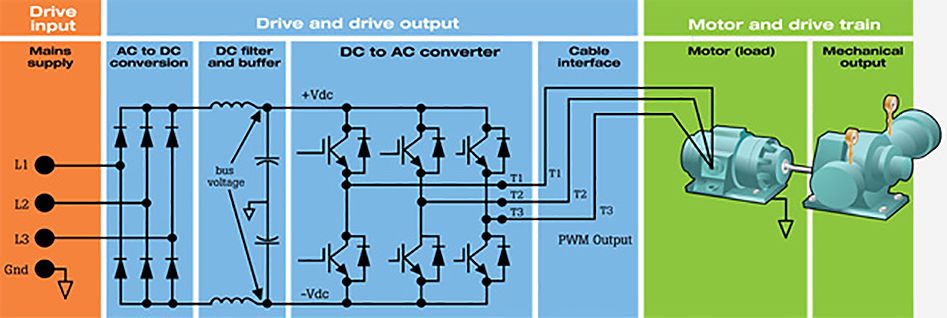

A VFD is both an electrical and electronic based frequency manipulation device with an intended purpose of:

● Taking AC power on the supply side

● Inverting that power to a DC voltage

● Storing that voltage in the VFD

● Using an internal technology of superfast switching technology called IGBT’S that will create a ‘sine wave-like’ form that can be manipulated by “altering the normal 60 HZ frequency” to an alternate value, thereby altering the speed of a 3 phase inductive or sometimes PM type motor.

Sounds simple right? At least the first three bullet points did… but this is where things can get a little tricky. While it is true that a VFD does “Invert” an AC line current, what is produced by the VFD is NOT a pure AC sine wave. What do I mean by this? This is where we tend to experience some confusion. It is a common belief that a VFD produces a pure AC sine wave just like a ROTARY PHASE CONVERTER (RPC), which is not the case.

What the VFD actually provides is a simulated sine wave via (PWM) pulse width modulation. The PWM output is actually just manipulated wave of DC output. In this disguised format, something like an AC INDUCTION motor cannot distinguish between the AC and DC waves.

The whole purpose behind the device is nothing more than matching required speeds necessary for process applications. This could vary from conveying system, fan/blower systems for pressure or flow requirements, speed necessary for spindles on machining centers and many other types of processing application used in all kinds of industry.

However, it is also this reason to which a VFD can’t be used as a “GENERAL POWER SUPPLY” to control machine, it’s specifically a MOTOR SPEED CONTROLLER. Any misapplication of this purpose can lead to equipment and or VFD failure.

Which applications can the VFD NOT be used on?

● Resistive loads (Welders, Ovens, Heaters, etc)

● Traditional 1 Phase motors with caps

● Equipment with a main control panel and (internal distribution) attempt to use a VFD as a power supply.

● Applying VFD to a machine with switches directly connected to motor (VFD needs to be directly connected to the motor) Open circuits create fires for instance.

In short, one should use a RPC to control an entire machine if it requires 3-phase power and use a VFD if one truly needs motor speed control and is directly connection to a AC induction motor that can handle the wave form as provided by the VFD controller. In using this simple logic, one will not have equipment failure again.

Chris Kinsfather

Post time: Oct-19-2022