EACON Inverter in Sand Drying Equipment Application

Sand drying equipment can dry river sand, dry mixed mortar, yellow sand, cement plant slag, clay, coal gangue, mixture, fly ash, gypsum, iron powder, limestone and other raw materials, and is widely used in building materials, chemical industry, casting and other industries. Brief description: Mainly used for drying fly ash, slag, sand, coal, iron powder, ore, blue carbon and other materials.

Processing introduction

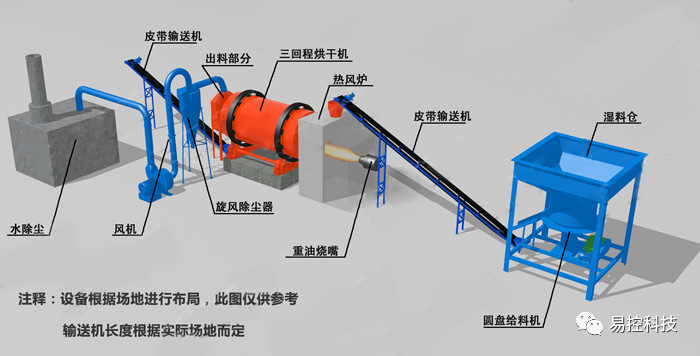

1. After the external sand passes through a section of water prevention and control, it is lifted by the loader to the upper silo of the disc feeder and poured into the feed silo; Under the action of gravity, materials contact the disc at the lower part of the silo. Driven by the motor, the disc is discharged to the lower belt conveyor in a fixed amount, and is pushed to the feed head of the dryer by the belt.

2. Before the materials enter the dryer, in order to reduce the mixing of cold air, the electric discharger is specially used for sealing.

3. After passing through the electric discharger, the material enters into the dryer and contacts with the hot air introduced from the superheater for heat exchange. When the material is repeatedly lifted with the rotation of the dryer, it is pushed forward, enters the middle cylinder from the inner cylinder and turns back, and flows to the discharge head when entering the outer cylinder. When the materials are discharged from the dryer, the electric discharger is still used to lock the air, and the sealing of the front and rear heads is made of graphite packing with sealing effect, which can limit the mixing of cold air, improve the internal temperature of the dryer, reduce the pressure burden of the induced draft fan, and also reduce the dust removal burden in the later period.

4. The temperature of the air after heat exchange decreases to 80-120 ℃ at the discharge end, while the humidity increases. Under the action of the rear induced draft fan, the air is subject to cyclone, bag type secondary dust removal (also can consider reverse water dust removal, water film dust removal, etc.), reaches the national emission standard, and is discharged outdoors through the chimney.

5. The whole drying process can be controlled by fully automatic PLC. The front and rear heads of the dryer are equipped with temperature measuring devices. The temperature display can be linked with the hot air stove, disc feeder, induced draft fan, and the frequency converter of the dryer host. Using the frequency converter can increase flexibility and ultimately save costs.

Post time: Nov-15-2022