Coal washing is an essential link to improve product quality in coal industry production, and an effective way to comprehensively utilize resources, save energy and protect the environment. Coal is easy to absorb water and evaporate in case of hot water; In the process of coal mining, coal slime cannot be directly used because of its high moisture content (about 20% – 40%), so dewatering and drying of coal slime becomes an indispensable step. Coal slurry drying not only pursues effect and efficiency, but also requires energy conservation and environmental protection to avoid secondary pollution. In addition, the high humidity of the working environment will also affect the efficiency of coal washing, and may also overload the electrical equipment and cause heat dissipation failure, thus causing accidents. Therefore, effective control of ambient temperature and humidity is the key factor to ensure efficient coal washing and safe and stable operation of electrical equipment. At the same time, it also puts forward high requirements for automation suppliers.

Equipment introduction:

The main equipment of the drying system is: dryer, coal-fired boiler, blower, induced draft fan, dust collector, scraper, feeding conveyor belt, product conveyor belt, belt discharge machine, unloader, etc.

The system adopts the direct drying technology: transport the coal slime to the drum of the dryer, control the rotation speed of the dryer according to the amount of coal slime and drying conditions, and the high-temperature drying flue gas generated by the coal-fired furnace flows through the drum of the dryer and fully contacts the coal slime in the dryer, making the moisture in the coal slime evaporate in the form of water vapor, and the wet and hot flue gas is pumped out by the induced draft fan after passing through the dust removal equipment. During the rotation of the dryer, the slime is gradually dried and discharged from the dryer drum.

The coal slime and drying medium are directly contacted in the dryer, which has good drying effect and high thermal efficiency. At the same time, the equipment structure is simple, and the single machine processing capacity is strong. Its disadvantage is that the wet and hot flue gas needs to be fully treated.

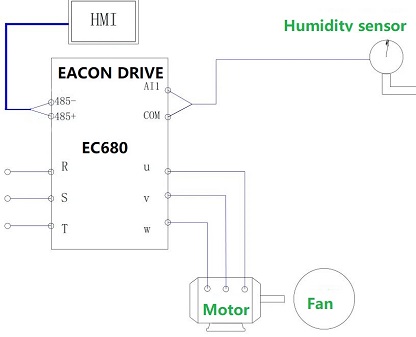

The electrical system of the equipment is equipped with multiple EACON EC680 (110kW, 220kW, 55kW and 15kW) series frequency converters on the dryer, induced draft fan, blower and scraper. Among them, six induced draft fans are equipped with six EC680 series inverters, which are controlled by high-performance closed-loop PID control. Real-time ambient humidity detection is carried out through the external humidity sensor, and the operating frequency is automatically adjusted according to the signal fed back by the humidity sensor, so as to keep the ambient humidity of the coal washing equipment consistent with the operating conditions of the equipment at all times. Some field pictures and parameters are as follows:

Application advantages

Realize smooth start and stop without impact, and extend the service life of mechanical equipment;

Perfect PID closed-loop operation ensures energy saving and efficient operation of equipment;

Wide speed regulation range, high speed stability accuracy, ensuring smooth operation of equipment, simple and easy operation;

Multiple protection functions: input and output phase loss protection, overvoltage, overcurrent, overload protection, etc;

It is suitable for field wide voltage input and has built-in automatic voltage stabilizing function to ensure safe and stable operation of equipment.

Post time: Feb-24-2023